Voedseletiketten en HACCP labels voor de voedingsindustrie

In de voedingsindustrie zijn veiligheid, traceerbaarheid en foutloze registratie essentieel. Toch ontstaan er vaak problemen met etiketten: ze laten los in vochtige omgevingen, vervagen door vet of kou, of zijn niet geschikt voor direct contact met voedingsmiddelen.

Dat levert risico's op voor audits, leidt tot fouten in batchregistratie en kan vertraging veroorzaken bij leveringen of terugroepacties. Vooral in gekoelde omgevingen of bij natte verwerking zijn standaardlabels onbetrouwbaar.

De oplossing is helder: voedselveilige etiketten die blijven functioneren onder alle omstandigheden. Etiketten die voldoen aan HACCP-normen, leesbaar blijven bij kou en vocht, en eenvoudig kunnen worden toegepast binnen bestaande processen, met of zonder eigen printer.

Voedingsindustrie

Op onze productielocatie in Heemskerk produceren wij diverse labels en etiketten voor de Voedings Industrie.

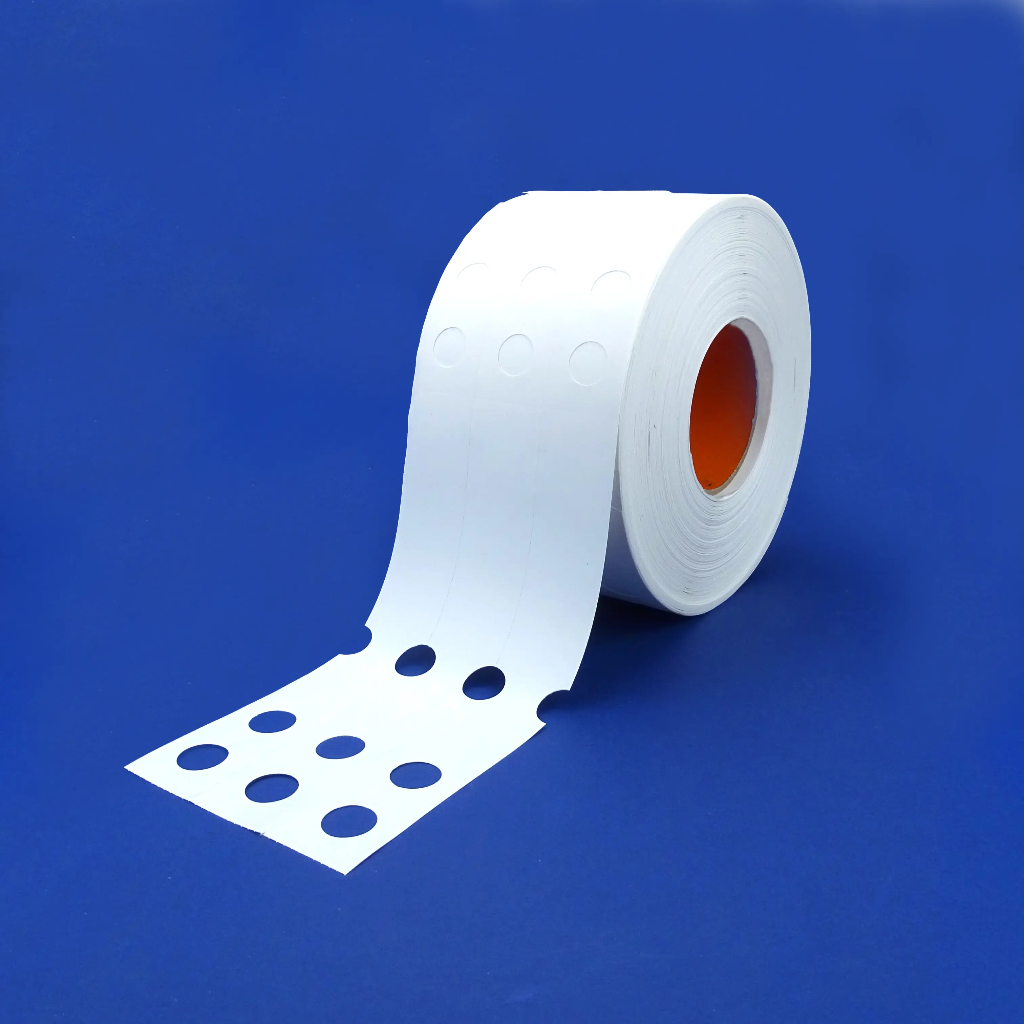

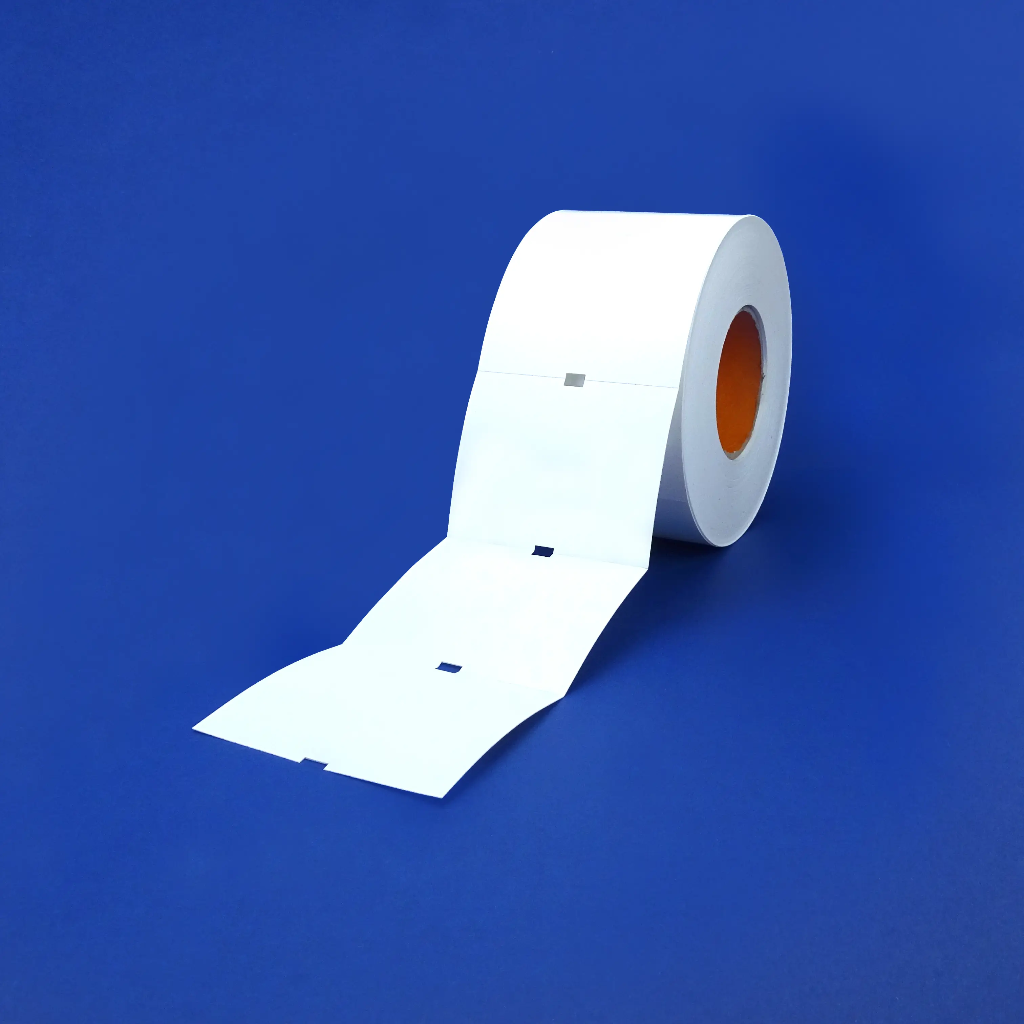

Standaardoplossingen voor voedselveilige labels

Voor veel toepassingen in de voedingsindustrie zijn standaardoplossingen beschikbaar die direct inzetbaar zijn. Deze etiketten zijn voedselveilig, praktisch in gebruik en geschikt voor verschillende soorten printers.

De etiketten zijn direct uit voorraad leverbaar in standaardformaten. Heeft u specifieke wensen voor maat, materiaal of bedrukking? Dan leveren wij maat werk labels die perfect aansluiten op uw process.

Klaar voor betrouwbare etiketten in de voedingsindustrie?

Of u nu etiketten zoekt voor kratten, verwerking, traceerbaarheid of klantorders, wij helpen u de juiste keuze te maken. Met slimme labels en printoplossingen versterkt u uw voedselveiligheid, voorkomt u fouten en houdt u grip op uw proces.

Offerte op maat

Ontvang een op maat gemaakte offerte die perfect aansluit op uw behoeften. Geen standaard pakketten, alleen gepersonaliseerde oplossingen.

Vul het formulier hiernaast in en ontvang een offerte op maat.